Description

Camet is capable of providing a full line of refractories to support the most demanding iron-making applications. One highlight is a metering nozzle changer which is a patent product for tundish, It is easy to meet the request for protecting casting and fast changing of all over 12.5mm nozzle.We product to meet the unique material specifications and demands of ladles and tundish. Camet commits its resources to achieve at least possible amount of spent refractory and the lowest operating costs. Our engineer would be happy to provide a upgrade design for customer's current changer system for tundish or making recommendations to enhance its more efficient.

Specification

For Ladle

|

Description |

Material |

|

Burned slide plates |

Aluminum-Carbon

Aluminum-Zirconium-Carbon Magnesia |

|

Unburned slide plates |

|

Slide plates installed metal bossor metal canned |

|

Preinstall slide plates with

lower nozzles |

|

Purging plug |

Corundum

corundum-spinel |

|

Lower nozzles (Collector nozzles) Upper nozzles (Ladle nozzles) |

Corundum

Aluminum- Zirconium-Carbon

Aluminum-Carbon |

|

Well blocks (Seating blocks) |

Corundum

corundum-spinel |

For Tundish

|

Applications |

Description of quick changer |

Main parts |

|

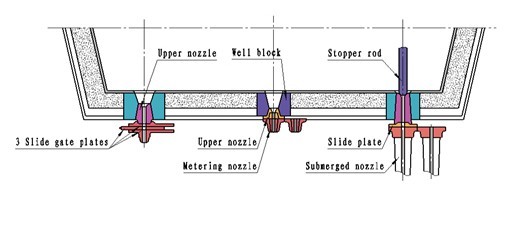

Slab caster |

Submerged nozzle changer |

Stopper rod |

|

Submerged nozzle |

|

Quick changer mechanism |

|

3 plates flow control |

Upper nozzle |

|

3 slide gate plates |

|

Well blocks |

|

Billet caster |

Metering nozzle quick changer |

Upper nozzle |

|

Metering nozzle |

|

Quick changer mechanism |

|